If you are currently searching for a single head automatic 12 needle embroidery machine price in Coimbatore, you are likely on the verge of making a significant decision for your business. Whether you are upgrading a home-based setup, expanding a fashion boutique, or managing a garment shop, finding the right machinery is crucial to your success.

Coimbatore is renowned as one of South India’s most dynamic textile hubs. However, navigating the market for industrial-grade embroidery machines can be overwhelming. You may be faced with generic listings, confusing import specifications, or uncertainty regarding after-sales support.

This comprehensive guide is designed specifically for you. It covers everything from pricing and technical specifications to local dealer details. Our goal is to provide you with a clear roadmap so you can invest with confidence, knowing you have the support of trusted local manufacturers like Julee (SS Creations) in nearby Tiruppur.

Table of Content:

- Why Coimbatore Buyers Look to Tiruppur for Embroidery Solutions

- Who is Julee (SS Creations)?

- What Is a Single Head Automatic 12 Needle Embroidery Machine?

- Julee’s Top Models for Coimbatore Buyers

- Pricing Guide: Single Head Automatic 12 Needle Embroidery Machine in Coimbatore

- Applications: What Can You Create?

- Buying Guide: How to Choose the Right Machine for You

- Suitability by User Profile

- Maintenance: Protecting Your Investment

- Frequently Asked Questions (FAQ)

- Conclusion

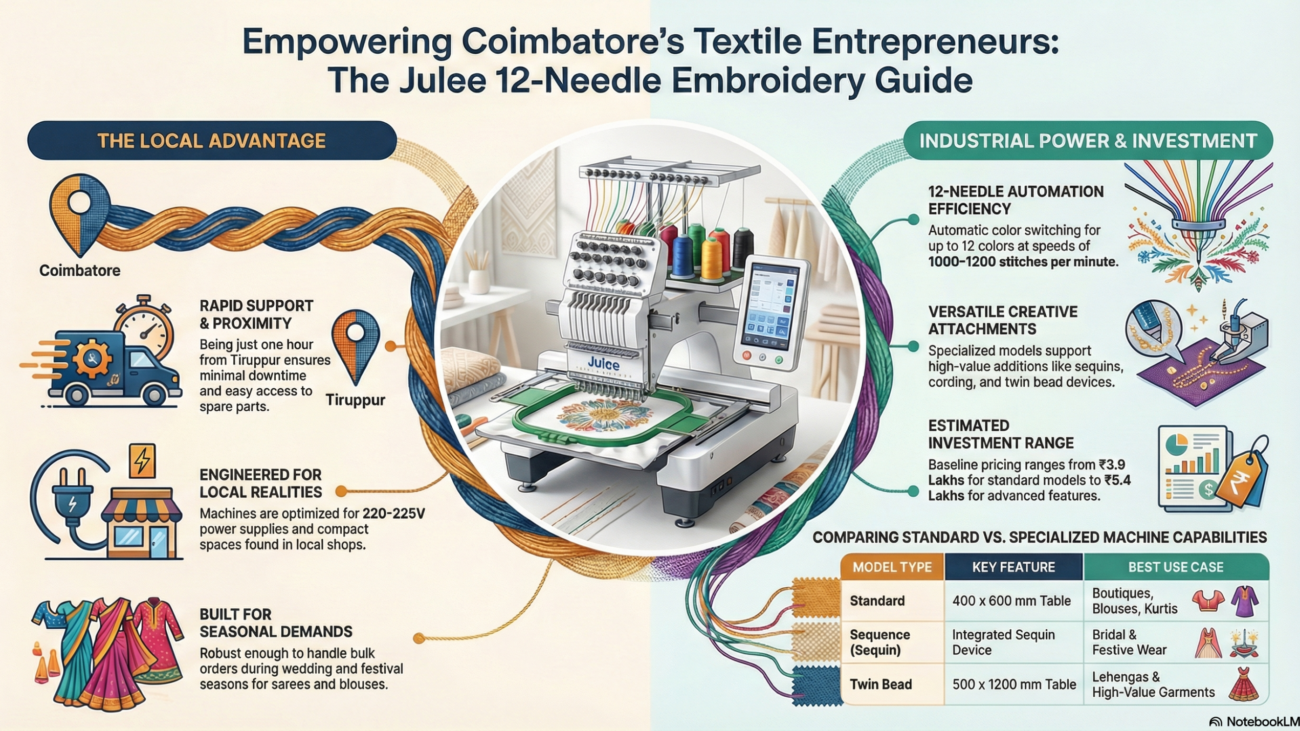

1. Why Coimbatore Buyers Look to Tiruppur for Embroidery Solutions

When looking for embroidery machines, many business owners in Coimbatore naturally turn their attention to Tiruppur. Located just an hour away by road, Tiruppur is not just a textile manufacturing hub; it has evolved into a sophisticated base for manufacturing the machines themselves.

1.1 The Advantage of Local Proximity

For a buyer in Coimbatore, relying on imported brands often means dealing with slow service responses and difficult access to spare parts. In contrast, sourcing from a manufacturer in Tiruppur, such as Julee (SS Creations), offers distinct advantages:

- Understanding Local Needs: Manufacturers in this region understand the specific day-to-day realities of your business.

- Rapid Support: You receive industrial-grade machinery backed by service teams that are geographically close, ensuring that downtime is minimised.

Tailored Solutions: Local suppliers understand the fabric types, workflows, and budget constraints typical of the Coimbatore market.

1.2 Addressing Coimbatore’s Business Challenges

Local manufacturers have designed their machines to solve specific problems faced by entrepreneurs in Coimbatore:

- Seasonal Demands: Machines are built to handle sudden peaks during wedding and festival seasons, perfect for blouse and saree work.

- Bulk Orders: They are robust enough to manage sudden bulk orders for uniforms, jerseys, and corporate wear.

- Space Constraints: The single-head design is specifically engineered for limited spaces found in small shops or home setups.

- Power Reliability: Recognising local infrastructure, these machines are optimised for 220–225 V power supplies, handling fluctuations better than some sensitive imports.

2. Who is Julee (SS Creations)?

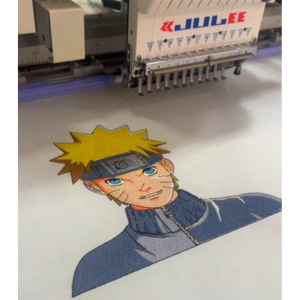

To understand the market for embroidery machines in Coimbatore, it is essential to know the key players. Julee is the flagship brand of SS Creations, a company established in 2004 in Tiruppur, Tamil Nadu.

2.1 A Legacy of Manufacturing

SS Creations is not merely a reseller; they manufacture and export a wide range of embroidery machinery. Their portfolio includes:

- Single head computerized embroidery machines.

- High-speed industrial models.

- Specialised machines featuring cording, twin sequins, and bead devices.

- Machines with extended work areas (up to 500 x 1200 mm).

2.2 Market Positioning

Julee’s positioning is strategic. They offer feature-rich, robust machines that match or exceed the capabilities of imported brands. However, they maintain pricing at a realistic level for Indian entrepreneurs. This approach has made them a primary destination for Coimbatore searches, as they provide a balance of quality and affordability that is hard to find elsewhere.

3. What Is a Single Head Automatic 12 Needle Embroidery Machine?

If you are new to industrial embroidery, you might be asking: “Where to buy a single head embroidery machine for home use?” or “What exactly does this machine do?”.

3.1 Understanding the "Single Head" Concept

A single-head embroidery machine features one main embroidery head. Unlike massive multi-head factory machines that take up entire floors, a single-head machine is compact. This makes it the perfect answer for boutiques and home studios that require industrial quality without the industrial footprint.

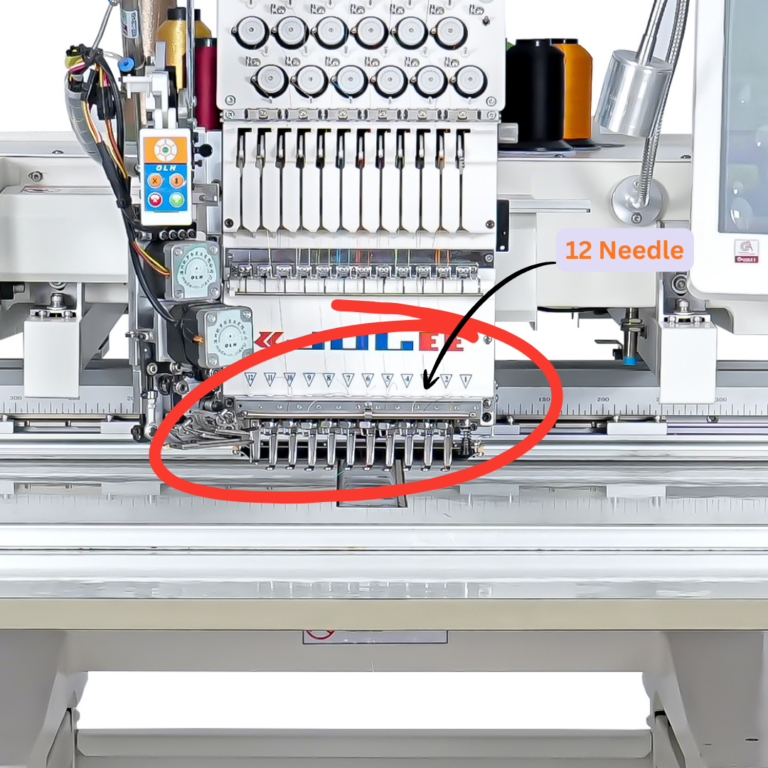

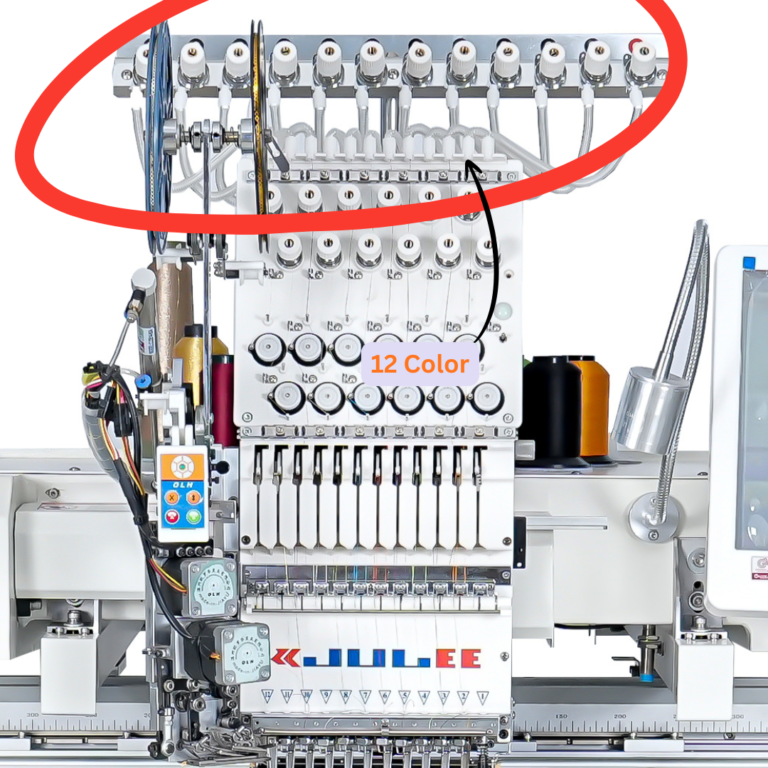

3.2 The Power of 12 Needles

The “12 needle” configuration is a game-changer for creativity and efficiency.

- Colour Flexibility: The head holds 12 different thread colours simultaneously.

- Automation: The machine automatically changes colours while running a design. You do not need to manually rethread the machine between different segments of a logo or pattern.

Design Depth: This allows for intricate borders, gradients, and multi-coloured logos that look professional and high-end.

3.3 Key Technical Traits

Julee’s 12-needle automatic single-head machines are defined by several high-performance specifications:

- Sturdy Build: Constructed with cast-iron or mild steel frames for maximum stability and reduced vibration.

- Speed: Capable of speeds up to 1000–1200 stitches per minute (SPM), depending on the specific model.

- Work Area: Common sizes include 500 x 1000 mm or 500 x 1200 mm, accommodating large garments like sarees.

- User Interface: Equipped with 10-inch touchscreen LCD panels featuring user-friendly menus for easy operation.

Voltage: Operates on standard 220–225 V, making it suitable for typical Indian electrical setups

4. Julee’s Top Models for Coimbatore Buyers

When you browse Julee’s product range, you will encounter several variants. Understanding the differences between these models will help you choose the right one for your specific needs.

4.1 Computerized Automatic Single Head Embroidery Machine (Standard)

This is the core industrial model, often the entry point for serious businesses.

- Worktable Size: 400 x 600 mm.

- Speed: 1000 SPM for flat stitches.

- Material: Cast-iron construction for durability.

- Best For: Boutiques designing blouses and kurtis, or shops handling mid-volume t-shirt and uniform orders. It strikes a perfect balance between size, speed, and price for the average Coimbatore user.

4.2 JL2040 + Sequence (Sequin Model)

For businesses focusing on bridal and festive wear, this model adds a layer of glamour.

- Special Feature: Integrated sequence (sequin) device for additional decoration.

- Speed: Up to 1200 stitches per minute on many flat jobs.

- Control: 10″ touchscreen with design preview capabilities.

- Best For: High-end boutiques requiring sequins for wedding blouses and heavy sarees. Visit here

4.3 JL-TM2048B+B (Twin Bead Device Model)

This model is designed for premium embellishment.

- Worktable Size: Extended area of 500 x 1200 mm.

- Special Feature: Bead device capability.

- Power: 1 HP consumption.

Best For: Long borders, lehengas, and high-value garments where beadwork commands a higher price. Visit here

4.4 JL-MY2040 (Large Area Model)

If your work involves home furnishings or large fabric panels, this machine offers the necessary space.

- Worktable Size: 500 x 1000 mm.

- Capacity: Approximately 45,000 stitches per hour.

Best For: Home furnishing creations and large garment panels. Visit here

4.5 JL-TM1624 (Cording and Twin Sequins)

This is the ultimate creative station for designers.

- Special Features: Easy cording and twin sequin capabilities.

- Speed: Max speed of 1200 SPM.

Best For: Designer studios where ornate detailing and unique textures are the core business offering. Visit here

5. Pricing Guide: Single Head Automatic 12 Needle Embroidery Machine in Coimbatore

One of the most common queries is regarding the single head automatic 12 needle embroidery machine price. While prices fluctuate based on market conditions and taxes, we can provide a realistic ballpark based on Julee’s listings.

5.1 Estimated Price Range

For a Coimbatore customer buying from Julee/SS Creations:

- Base Models: Standard single-head machines (often including cording capabilities) are typically priced around ₹3,90,000.

Advanced Models: Machines equipped with multi-function features like sequins or beads are generally listed around ₹5,40,000

5.2 Factors Influencing Price

- Factory Direct: The price you pay is typically similar to the factory price in Tiruppur (₹4.2–4.9 lakh range).

- Add-ons: Accessories such as cap frames, specialized beading devices, twin sequins, or laser cutting attachments will increase the total cost.

- Logistics: Delivery involves a modest transport charge from Tiruppur to Coimbatore, which is usually a minor part of the total investment.

- Taxes: GST is applicable at current rates on machinery.

Note: For the most accurate and current pricing, it is highly recommended to contact Julee directly for a quotation. The ₹4–5 lakh range is a solid baseline for your budget planning.

6. Applications: What Can You Create?

Investing in a Julee machine opens up a vast array of creative possibilities. The versatility of a 12-needle single-head machine allows you to shift between different market segments without needing multiple machines.

6.1 Traditional Apparel

Coimbatore is famous for its ethnic wear. These machines are perfect for:

- Blouses and Sarees: Create intricate borders and motifs using cording and sequins.

- Kids’ Ethnic Wear: Produce colourful, detailed designs for festive occasions.

- Sherwanis: Handle heavy fabrics and elaborate patterns.

6.2 Western Garments and Uniforms

For the corporate and casual market, these machines offer high-speed efficiency:

- Branding: Embroider logos on t-shirts, hoodies, and denim jackets.

- Monograms: Personalise shirts and accessories for premium clients.

6.3 Accessories and Home Décor

Expand your product line with:

- Small Items: Caps, socks, sleeves, and tote bags (using appropriate frames).

Home Furnishings: Cushion covers, table runners, curtains, and wall hangings, especially using the larger work area models.

7. Buying Guide: How to Choose the Right Machine for You

To ensure you make the best investment, follow this step-by-step buying guide tailored for the Coimbatore market.

Step 1: Define Your Use Case

Be clear about your business model.

- Home User: Do you need a machine that fits in a spare room?

- Boutique: Are you focusing on high-margin bridal wear?

Shop: Are you targeting high-volume uniform orders?

Step 2: Decide on Work Area

Choose a worktable size that fits your primary product.

- 400 x 600 mm: Sufficient for most apparel, t-shirts, and logos.

500 x 1000 mm / 500 x 1200 mm : Essential for long borders, saree pallus, or home furnishing panels.

Step 3: Select Attachments

While 12 needles are standard, the attachments define your niche.

- Cording Devices: Ideal for textured outlines and calligraphy.

- Twin Sequin Units: Necessary for sparkling bridal and party wear.

- Bead Attachments: For premium, high-value embellishments.

Tip: If you are just doing basic logos, a simpler machine is cost-effective. If you run a boutique, cording and sequins are worth the extra cost.

Step 4: Verify Technical Specs

Ensure the machine meets industrial standards.

- Speed: Look for 1000–1200 SPM for productivity.

- Build: Confirm cast iron or mild steel frames for stability.

Power: Ensure it runs on 220–225 V and has ISI certification.

Step 5: Plan Your Budget

Use the ₹4.20 lakh to ₹4.90 lakh range as a guide.

- Financing: Ask about financing options from local banks.

- Total Cost: Factor in GST and transport.

Bundles: Look for offers that include hoops, frames, or design software.

Step 6: Evaluate After-Sales Support

This is where buying from Julee in Tiruppur pays off.

- Technician Access: Expect faster visits compared to imported brands.

- Spare Parts: Enjoy ready availability of parts.

Training: Get guidance on troubleshooting and design file handling

8. Suitability by User Profile

Different buyers in Coimbatore have different requirements. Here is how Julee’s machines fit various profiles

8.1 For Home Users

If you are searching for “where to buy single head embroidery machine for home use,” these machines are surprisingly suitable.

- Compact Footprint: They can fit into a balcony workstation or spare room.

- Manageable Power: With 1 HP power consumption and 220 V compatibility, they don’t require heavy industrial wiring.

Automation: The automatic features allow you to run a side business without needing factory-level skills.

8.2 For Fashion Boutiques

Boutiques specialising in bridal blouses, lehengas, and custom designs need versatility.

- Creative Features: Models like the JL-TM2048 offer cording and twin sequins, transforming your ability to offer unique designs.

- Large Workspace: The ability to handle borders and yokes is crucial for saree work.

8.3 For Garment and Uniform Shops

Shops supplying schools or corporates need speed and consistency.

- High Volume: With speeds up to 1200 SPM and capacities like 45,000 stitches per hour, you can meet deadlines reliably.

Ease of Management: Single-head machines are easier to schedule and maintain for smaller teams compared to complex multi-head units.

9. Maintenance: Protecting Your Investment

A machine in the ₹4–5 lakh range is a serious asset. Regular maintenance is key to its longevity.

9.1 Daily and Weekly Care

- Cleaning: Brush out lint from the needle area, bobbin case, and thread paths at the end of every day.

- Lubrication: Strictly follow the manufacturer’s oiling recommendations for moving parts.

Needles: Replace needles regularly or immediately if you notice fraying or thread breaks.

9.2 Operational Best Practices

- Thread Quality: Use high-quality embroidery thread to protect tensioners and prevent breakage.

Power Protection: Given local conditions, always use stabilizers or UPS units to protect the machine from power fluctuations.

9.3 The Local Service Advantage

Because SS Creations is based in Tiruppur, you have a safety net. Spare parts and professional service are much easier to obtain compared to imported machines, ensuring your business stays up and running.

10. Frequently Asked Questions (FAQ)

Here are answers to the most common questions regarding embroidery machines in Coimbatore.

Q1: What is the typical single head automatic 12 needle embroidery machine price in Coimbatore?

A: Buyers sourcing from Julee in Tiruppur can expect a price range of roughly ₹3.9 lakh to ₹4.9 lakh plus taxes. This depends on the specific model and whether you add features like sequins or beading devices.

Q2: Are these machines really suitable for home use?

A: Yes. The single-head 12-needle machines are designed with a compact footprint and operate on 1 HP / 220 V power, making them very viable for home-based businesses, provided you have the space.

Q3: Can I use the same machine for boutique work and bulk uniform orders?

A: Absolutely. These machines are versatile. Many boutiques use them for intricate designer work, while also utilising their high speed for small bulk runs when necessary.

Q4: How difficult is it to learn how to operate the machine?

A: Julee’s machines feature a 10-inch touchscreen control panel and computerized automation. They are designed to be approachable for tailors and entrepreneurs, even those new to automated embroidery.

Q5: How do I buy a Julee machine in Coimbatore?

A: You can contact SS Creations/Julee directly through their official website or contact numbers. They supply machines from Tiruppur, handle installation at your location in Coimbatore, and provide local support.

Conclusion

Searching for the right single head automatic 12 needle embroidery machine price in Coimbatore leads to one clear conclusion: the best value and support lies just next door in Tiruppur.

By choosing a locally manufactured machine from a reputable brand like Julee (SS Creations), you are not just buying a piece of hardware. You are investing in a partnership that understands your market, offers reliable service, and provides the versatility to handle everything from bridal sarees to corporate uniforms.

Whether you are a home entrepreneur or a boutique owner, these machines offer the industrial power you need with the local support you deserve. We hope this guide has clarified your options and helps you take the next step in growing your textile business.

For the latest quotations and specific model availability, we recommend reaching out directly to Julee (SS Creations) in Tiruppur. Fill the form, a representative will reach you shortly.