For garment manufacturers in Tirupur, choosing the right machinery is a balancing act. You need something fast enough to handle volume, precise enough for complex designs, but compact enough to fit in a smaller unit.

Enter the Julee JL1624. This machine has become a popular choice in the single-head market. It offers the versatility needed for sampling and small-to-medium orders without the massive price tag or floor space required by giant multi-head machines.

In this guide, we break down everything you need to know about the Julee JL1624—from its technical specs and price to exactly how to set it up in your factory on PN Road or Appachi Nagar or anywhere in Tiruppur, Tamil Nadu, India.

1. What Makes the Julee JL1624 Special? (Technical Specs)

The Julee JL1624 is a fully automatic single-head embroidery machine. But what does that mean for your daily production? Here is the breakdown in a few points.

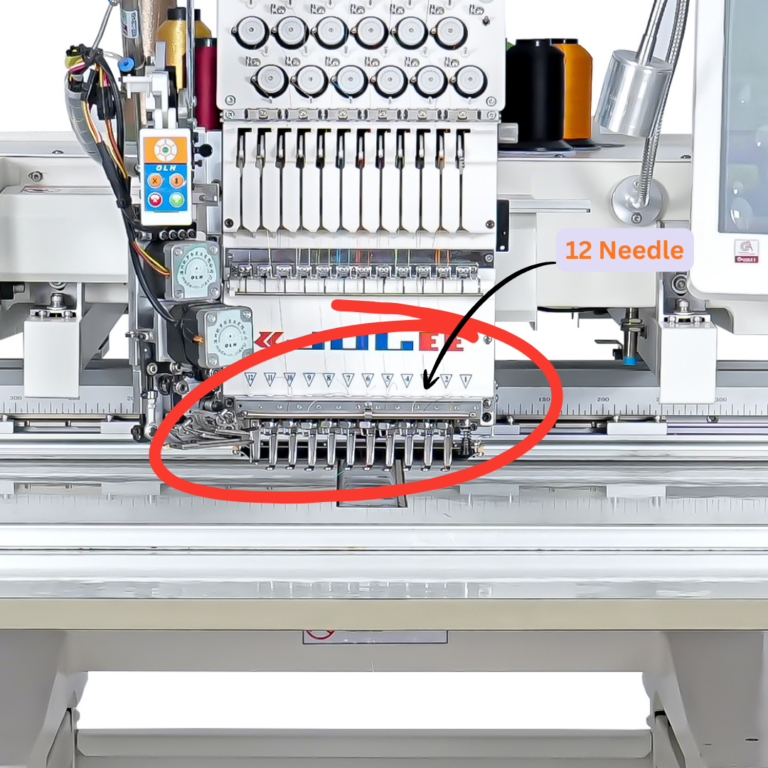

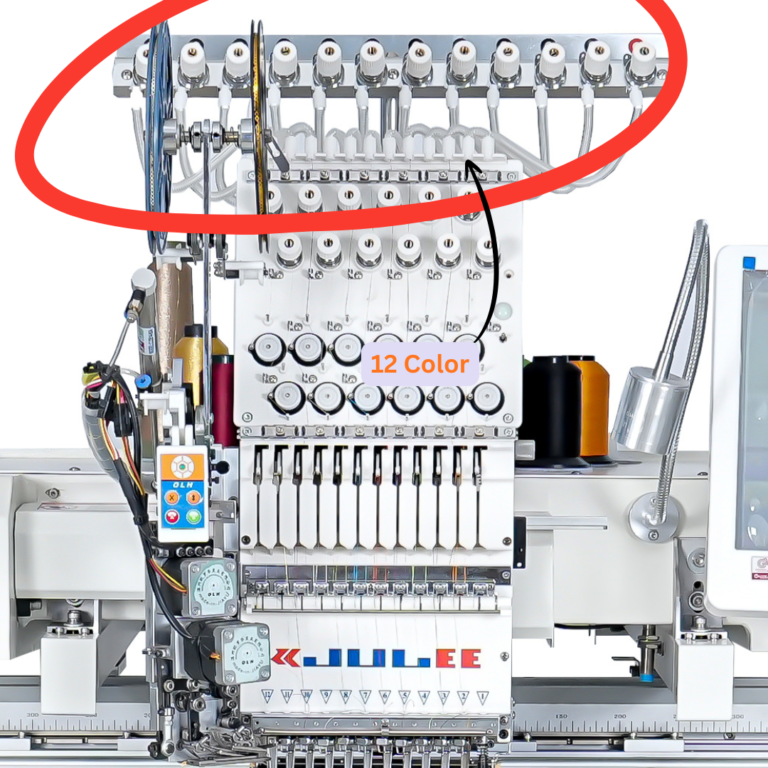

12 Needles = 12 Colors

The standout feature is the 12-needle configuration.

- The Benefit: You can thread 12 different colors at once. When the design changes color, the machine automatically switches needles.

- Why it matters: You don’t have to stop the machine to manually change threads. This saves huge amounts of time on colorful designs like saree borders or kids’ wear.

Large Work Area

Most compact machines have tiny worktables. The Julee JL1624 offers a generous 400mm x 600 MM worktable (though some local setups might be interested on 500 x 1000 MM, 500mm x 1200mm and so on).

- Real-world use: This size is perfect for handling the fabric panels or elaborate saree borders without needing to constantly re-hoop the fabric.

Speed & Build

- Speed: It runs at roughly 1000 RPM (Rotations Per Minute). While some other variations hit 1200 RPM (you can check JL MY1624, JL TM1624 and etc), 1000RPM is a “sweet spot” that balances speed with thread safety (less breakage).

- Build: Made with Mild Steel (MS), it is heavy enough to stay stable and not vibrate excessively during high-speed stitching.

- Power: It runs on standard 220V (Single Phase), meaning it works with the standard power setup found in most Tirupur industrial sheds

2. Pricing Analysis: What Does it Cost in Tirupur?

Budget is usually the deciding factor. The Julee JL1624 sits in the “Base-Range” category—it is more reliable than cheap generics but far more affordable than high-end Japanese brands.

Here is the current market snapshot for 12-needle models:

| Machine Type | Approx. Price Range |

|---|---|

| Generic Single-Head | Starting at ₹ 4,30,000 |

| Julee JL1624 (Standard) | ₹ 3,90,000 |

| Julee (Premium/Package) | Up to ₹ 5,40,000 |

Buyer’s Tip: These prices often exclude GST and shipping

3. Setting Up Your Home Factory: A Checklist

Buying the machine is just step one. To get the Julee JL1624 running smoothly in hubs like PN Road or Palladam, you need to prepare your floor.

Step 1: Space Planning

Don’t underestimate the footprint. Even though the machine is compact, the moving frame needs room.

- Machine Weight: ~300 kg.

- Clearance: You need at least 5×5 feet of clear space per machine. This ensures the hoop can move freely without hitting a wall and gives your operator room to work.

Step 2: Power Protection

The machine uses computerized panels that are sensitive to power spikes.

Requirement: Since industrial zones often have voltage fluctuations, installing a good Industrial Stabilizer is mandatory to prevent frying the motherboard.

Step 3: Local Support & Maintenance

You need to know who to call when things break. Fortunately, Tirupur has a strong support network for this brand:

- Dealers: SS Creations (Ramaiyah Colony, Muniyappan Kovil Street, Near Miller Stop) and Julee Embro Tech Pvt Ltd (same location of SS Creations) are verified suppliers for Julee models. You can talk to them directly on: +91 88254 78070

Service: For repairs and technical support, SS Creations & Julee Embro Tech has specialized technicians in units, ensuring your downtime is minimal.

Conclusion: Is it Worth the Investment?

The Julee JL1624 is a smart investment for manufacturers who need to step up from basic sewing but aren’t ready to spend ₹12 Lakhs on a Japanese unit.

With a price point between ₹ 3.9L and ₹ 4.4L, it offers the professional 12-needle capability and frame size needed for serious home work. It is specifically well-suited for units producing samples, saree borders, or medium-volume detailed embroidery.